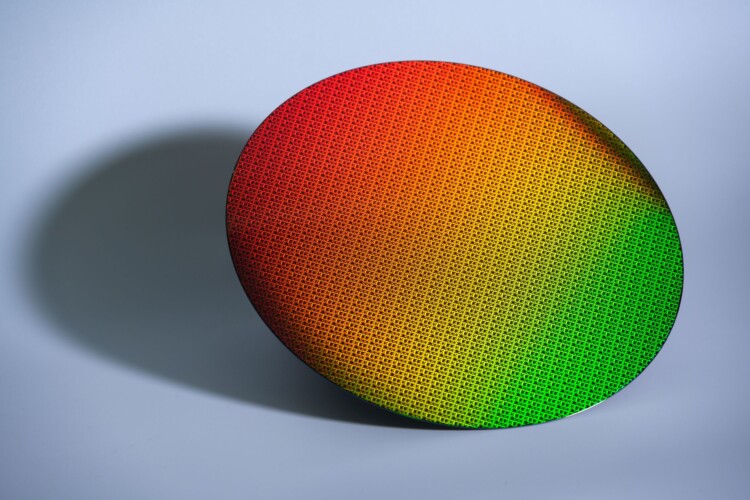

Intel recently gave an update on its 18A process: it is now ready for customer projects and tape outs are set to being within the first half of 2025. The new node is expected to take on TSMC’s N2 process, which itself is expected to make its debut within 2026.

18A, short for 18 Angstrom or 1.8nm, is expected to yield up to 15% better PPW and 30% better chip density than the current Intel 3 node. It is also expected to be the first of its kind to use PowerVia backside-power delivery technology, with an improved density and cell utilisation between 5% and 10%.

Intel 18A will also be built using RibbonFET gate-all-around (GAA) transistor technology that the company says will “enable precise control of electrical current. RibbonFET allows further miniaturization of chip components while reducing power leakage, a critical concern for increasingly-dense chips.”

TSMC is also preparing its own GAA architecture with its 2nm N2 process node but unlike the Intel 18A, the Taiwan fab isn’t expected to tape out its process until 2026, at least.

Not too long ago, Intel 18A’s process became a subject of controversy when reports (we were one of them, admittedly) stated that the process node had a yield of 10%. It took Pat Gelsinger, former CEO of Intel, to point out that the defect density of the process was low and that, at the time, the yield for it was at 99%.

Follow us on Instagram, Facebook, Twitter or Telegram for more updates and breaking news.