The Malaysian government has launched the forward-thinking 2020 National Graphene Action Plan (Pelan Tindakan Graphene Kebangsaan 2020), with an ultimate aim of generating RM9 billion in revenue and creating 9000 jobs by 2020. Felda Global Ventures Holdings Berhad is already in the process of building a graphene manufacturing plant in Cambridge, with an expected opening date of October this year.

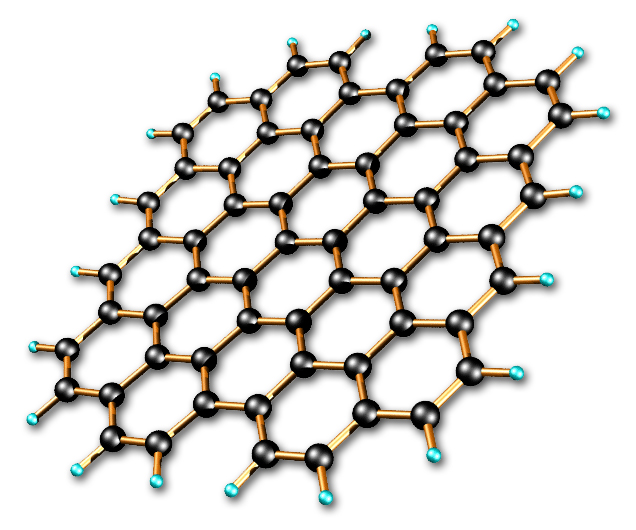

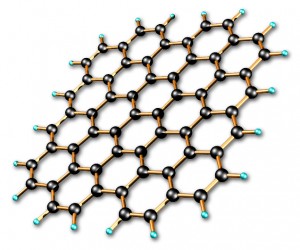

Known as the world’s strongest material, graphene’s inherent properties include a breaking strength that is 300 times greater than that of steel – but is only one atom thick, giving it a two-dimensional shape. Also, it is flexible and conducts electricity better than copper. Due to these properties, graphene is expected to replace silicon as the base for all electronics in the future.

The action plan is jointly developed by the National Agency for Innovation (Agensi Inovasi Malaysia – AIM), the Performance Management and Delivery Unit (Unit Pengurusan Prestasi dan Perlaksanaan – PEMANDU) and NanoMalaysia Berhad. This plan was made based on research about Malaysia’s potential for graphene development and its possible value for the country’s economy.

According to Senator Datuk Seri Idris Jala, the plan will focus on these aspects of graphene development: lithium-ion anode batteries, ultra-capacitors, rubber additives, nano-drilling liquids, lubricants, conductive ink and plastic additives.

The action plan will see the bodies involved dovetailing each other in their own roles. AIM CEO Mark Rozario states that NanoMalaysia Berhad has been appointed to be the pioneering agency to implement the plan, while a committee headed by Datuk Seri Idris as well as the Trade Minister and the Science, Technology and Innovation Minister will be set up to monitor the plan’s implementation.

Meanwhile, Felda Global Ventures Holdings Berhad is expected to begin mass production of the super material once its production plant in Cambridge opens in October this year. Felda chairman Tan Sri Mohd Isa Abdul Samad states that the plant will be able to begin production of graphene as early as the end of this year or early 2015.

While graphene has been on the radar of the tech industry for years now, the one major stumbling block for the mass adoption of the material is in the costs related to mass-producing it: it’s prohibitively expensive. However, three months ago, South Korean electronics giants Samsung revealed that the company has found an alternative method for crystalising graphene in a way that it retains its electrical and mechanical properties. Further back, Nokia – who has been dabbling with graphene research since 2006 – was given a €1b grant to research applications for the material to be used in the electronics and mobile industry.

(Sources: Bernama, Utusan Malaysia)

Follow us on Instagram, Facebook, Twitter or Telegram for more updates and breaking news.