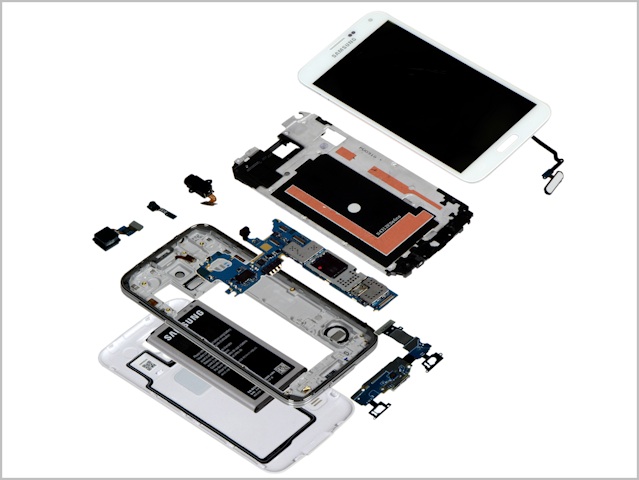

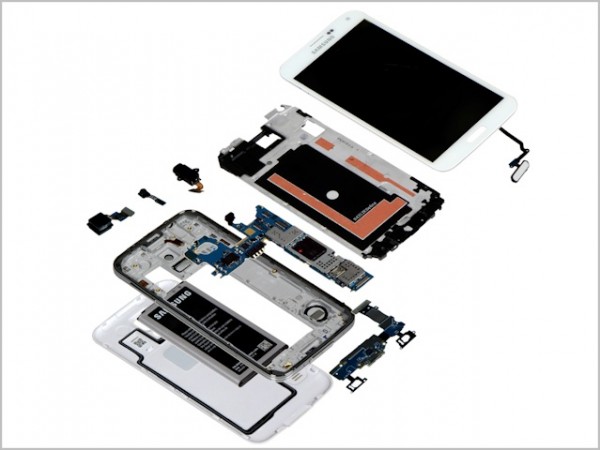

The Samsung Galaxy S5 may seem like one heck of a device, featuring a IP67 rated build for dust and water resistance and packing all the latest and greatest hardware under its 5” hood, but how much does it really cost to make the latest flagship smartphone from Samsung? According to a teardown analysis by market research firm, IHS, the answer is about USD$256; the device retails at USD$600 in the U.S. without a contract.

“Inside we see mostly a lot of recycled components that we’ve seen before. There’s really nothing special inside where Samsung is pushing the envelope. There’s no breakthroughs, there’s nothing earth-shattering. It’s really just a continuation of what has come before.” – Andrew Rassweiler, an analyst in IHS.

The most expensive component in the entire display would have to be the 5” Super AMOLED display, which costs about $63. The DRAM and flash memory, which is supplied by the Korean company themselves, costs about $33 combined.

IHS’ report also mentions that the processor used in the phone is a Qualcomm Snapdragon 801, a chip seen in many other phones recently like from Nokia and LG. Although it’s faster than previous generations, Rassweiler notes that there they’ve seen a plethora of phones with that chip.

As for the fingerprint sensor, IHS says that it costs about $4, significantly cheaper than Apple’s iPhone 5S’ fingerprint sensor that costs about $15. Other prices mentioned in the report includes the $1.45 biosensor that is capable of measuring personal health data, as well as estimated cost of assembly of $5 per unit.

The estimated cost is for manufacturing a Samsung Galaxy S5, and does not include the cost of software, distribution or marketing, of course. For comparison’s sake, the iPhone 5S costs about $199 to build and sells at a price ranging from $649 to $849 depending on the capacity.

(Source: Re/code, AllThingsD)