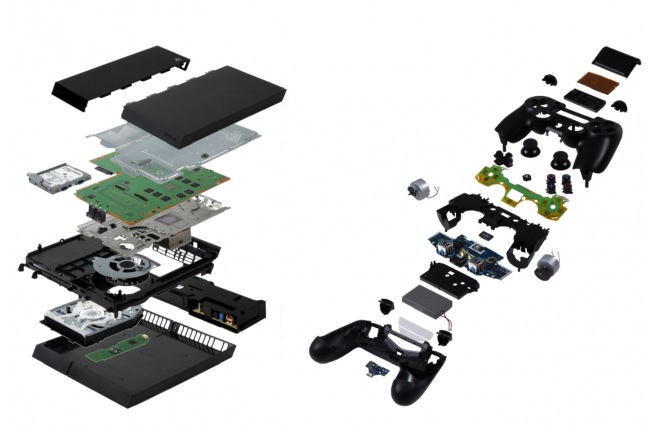

A teardown of Sony’s next-gen gaming console reveals that the it costs around $381 to build the PlayStation 4 – only $18 lower than the $399 retail price it is going for in the US. Factor in the R&D and marketing costs, and it is likely that Sony is selling the PS4 at a loss.

IHS iSupppli, which has garnered a reputation of accurately estimating the cost to build a device based on its components, recently gave the PS4 the teardown treatment and estimates that the total cost of the parts, including the costs to assemble them, to be $381. It is largely due to the microprocessor and memory chips, which made up about half of the total manufacturing cost of the console at about $188.

Selling consoles at a loss has been a strategy that’s been employed since Sony’s last console, the PS3. Back then, the loss made on each console was more drastic – the $599 console cost an estimated $805 to build. The idea behind this was to ensure consumers purchase a cheaper console and lock them in to the ecosystem and make greater profits in the long run from game sales – a strategy that is similar to Google’s cheap Nexus flagship Android smartphones.

Check out the full analysis of the teardown at the source link below.

(Source: AllthingsD via Ars Technica)

Follow us on Instagram, Facebook, Twitter or Telegram for more updates and breaking news.